Improvement of cement performances through .

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill ''Arcangelo, – Mapei SpA ...

WhatsApp)

WhatsApp)

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill ''Arcangelo, – Mapei SpA ...

• What is Cement? • History • Overview of the Cement . cement mill clinker gypsum 95% 5% additive up to 15% Separator Fines Finish Grinding System Rejects .

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV Submitted to the Office of ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Brochure D/EN | PDF LOESCHE. the quality of cement obtained from VRM grinding is as good as, or in some cases better than, that produced in a ball mill In ...

2 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by

A Publication of the Lubrication Engineers Technical Department LEADERS IN LUBRICANTS NUMBER 102 LUBRICATING GRINDING/PULVERIZING MILLS WITH .

The Horomill is a compact mill that can produce a finished product in one step and hence has relatively low ... Cement grinding with Horomill Publications. ... PDF ...

Sep 08, 2016· Hello, we are doing mining equipment manufacturers, you see our products, please consult: Now chatting: You can ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons .

be applied in cement grinding optimisation. Only the cement clinker grinding is discussed ... grinding balls from leaving the mill. A proportion of material, ...

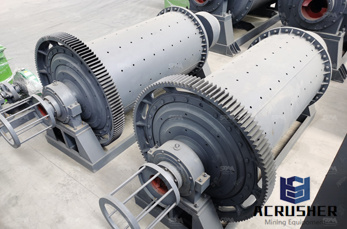

Grinding in Ball Mills: Modeling and Process Control ... Grinding in ball mills is an important technological process applied to ... metallurgy, cement production, ...

Cement grinding is the single biggest consumer of electricity in the manufacturing process. 5 ... Ball mill improvements Maintaining grinding efficiency

Finish Grinding; Grinding Aids for Ball Mills; ... The aid also improved the dispersibility and fluidability of cement ... org/pdf/Projects/Cement/APP_Booklet_of ...

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

Grinding trends in the cement Download as PDF File (.pdf), Text File (.txt) or read online.

pdf vertical grinding mill for cement free manual,. Brochure EN PDF 4,3 LOESCHE . In 1935 Loesche supplied a first cement mill to. Brazil.

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill ...

LoescheMills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

The various types of grinding systems currently being used for cement grinding in a cement plant are: • Conventional tube mill Open and Close circuit

Aug 23, 2012· fls cement mill pdf Crusher Manufacturer. Cement mill Wikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the ...

Portland Cement Manufacturing Process Description17 ... In the wet process, water is added to the raw mill during the grinding of the raw materials in

Feb 10, 2016· re VRM vs Ball Mill for Cement Grinding. Specific power consumption high for ball mill ... cpbsem2015p01cement grinding an overview and improvement ;

WhatsApp)

WhatsApp)